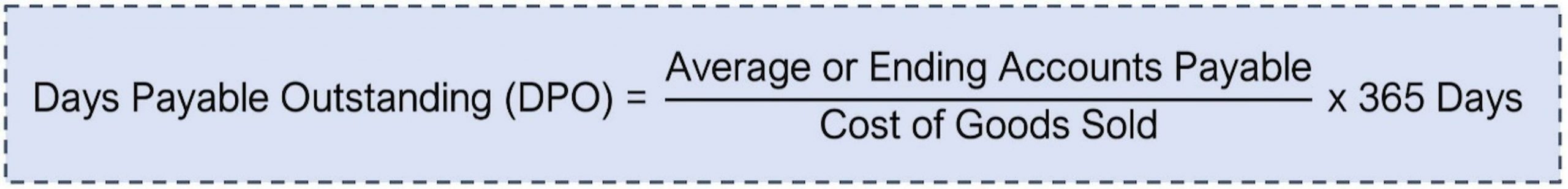

You can find this number by adding up your daily orders and dividing it by the number of days in the period. For instance, if you add up thirty days of orders and get 300, you would divide it by 30. Reorder point planning is an early approach to supply chain planning; however, while often dismissed as passé, it has applicability in several circumstances.

- This is the more basic version, used when you don’t need extra buffer inventory.

- Implementing these strategies will position your business for greater success and sustainability.

- Warehouses and distribution centers focused on growth, efficiency, and scalability use warehouse management systems (WMS) and inventory management systems instead of Excel spreadsheets.

- Sales volume is another important factor to consider as it pertains to setting safety stock for reorder point calculations.

- On the other hand, ROP measures the effectiveness of advertising campaigns in generating sales or revenue.

Calculating Reorder Points Are An Inventory Management Best Practice

Including Safety Stock – that essential buffer against the unpredictable elements of demand and supply – adds another layer of security. By organizing your data and utilizing formulas, you can monitor inventory levels and determine when to reorder. The article provides a detailed tutorial and even https://hostilehooliganz.com/goods-received-note-full-form-of-grn-importance-3/ offers a downloadable Excel template to assist you.

Reorder Point in Retail Industries

Printing advertisement isn’t just a way for newspapers and magazines to generate profit. Ads are part of the reading experience and publications use them to increase engagement with the audience. They also play an important role in the aesthetics and visual identity rop meaning business of the publication. This is especially true for ROP ads since they share space with editorial content and readers often actively check them out. Advertising your business on print media is a great way to increase brand exposure and generate leads.

Understanding the Reorder Point Formula in Inventory Management

In conclusion, ROP is a valuable tool for businesses to evaluate the financial impact of their marketing promotions. By measuring the return on promotion, businesses can make data-driven decisions and optimize their marketing strategies to achieve the best possible results. This issue is one example, but there are many more questions and ways of optimizing supply planning by addressing questions just like this one for each company. If this is something you are interested in, contact us at the chat widget in the lower right hand corner, or at This is the ability to see the relationship between changes to service levels and the simulated output. Set the supply planning parameters in a way that one can simulate the impact on the overall supply plan.

Final thoughts on the reorder point and its importance in inventory management

- The ROP metric can be used to compare different promotional strategies and tactics, allowing businesses to optimize their marketing efforts and allocate resources more effectively.

- This approach will assist in preventing the overestimation or underestimation of demand.

- Since the start of the digital age, computers and smartphones have slowly taken over our lives and affected how we follow news and events.

- It allows for agile responses to market changes, supports data-driven decision-making, and fosters a proactive approach to logistics management.

- This understanding includes taking into account variables such as lead time demand, safety stock levels, and supplier reliability when calculating ROPs.

Factors such as inventory flexibility, projected future demand and supplier lead times should all play a determining role. Sales volume is another important factor to consider as it pertains to setting safety stock Accounting Periods and Methods for reorder point calculations. So how do you calculate the demand during lead time and safety stock metrics to help determine reorder point?